Last November, I devised a new compact pcb footprint on a 50 x 50mm board, and I have started to create a number of boards based on this format.

In November's blogpost, I speculated about using the board as a universal format for creating small microcontroller and FPGA boards, which share common peripherals and a standard pin-out ports for interconnectivity and "stackability".

The boards are fitted with "Arduino like" expansion shield headers - which themselves have been extended to provide connection for up to 28 GPIO signals, arranged nominally in four headers A, B, C, D.

The ports have been generally based on the arrangement on the ATmega1284, which in a 40 pin DIL package provides four, 8 bit ports with the power pins & clock oscillator pins located towards the centre of the package. This a compact, logical arrangement, which makes the most of what can be packed into a 40 pin DIL. (In the late 1970's manufacturers were very resourceful on how to package an 8 bit microprocessor with 16 address lines into the standard 40 pin DIL package).

The purpose of the breakout board is to put a complete microcomputer system into an easy to use, compact format. This was the strategy adopted with WiNode which uses the ATmega1284, but which I am now extending to allow for further offerings from ARM and FPGA devices.

With ever increasing sophistication of microcontroller products, the pin-counts are rapidly rising - so it becomes a challenge on just how to access all of the GPIO pins for breakout, especially when some LQFP packages have 208 pins!

Whilst the extended Arduino headers can handle up to 28 GPIO, clearly another strategy is needed for the larger packages.

From my experience with WiNode, it is very easy to quickly use up several GPIO lines just supporting the on-board peripheral hardware devices:

microSD card SPI bus + /CS

RTC I2C + interrupt

SRAM SPI + /CS

Keyboard Clock, Data,

Mouse Clock, Data

Wii Nunchuck I2C

FT812 SPI, /CS

USB UART RX0, TX0

WiFi (ESP-01) RX1,TX1

RFM69 SPI + /CS + interrupt

Battery Volts ADC

Battery Temp ADC

So 20+ lines can easily be consumed with the on board devices. Incidently, the WiNode 5 has been designed so that it will support other processors in addition to the ATmega1284, in this role it becomes a compact I/O shield.

ARM Challenge

Adopting this format to the larger parts will require a different strategy. Do we assume that almost all of the "Arduino" pins will be consumed with the local peripherals and that a bus strategy should be employed for inter-board communications?

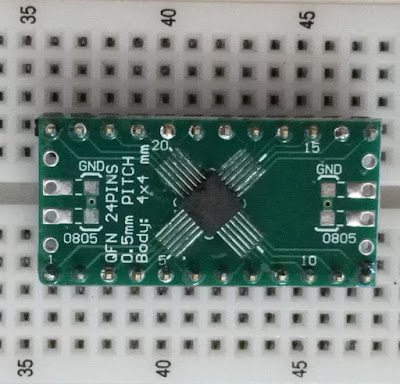

For ARM packages up to 48 pins, the solution is to craft the device GPIO ports into a 40 pin DIL format, such that it can be plugged directly into the WiNode board. This will take care of the essential system peripherals, leaving the remaining lines available for a bus connector.

On the ARM processors, this is likely to connect directly to the Flexible Memory Controller (FMC). As this is involves a lot of signals, a more dense connector format will be required - and 1.27mm pitch would double the connector density yet remain compatible with 2.54mm standard pitch connectors.

The larger package ARM processors have the FMC external memory controller and also a parallel LCD controller interface - both of which are very intensive in terms of pin usage. These should be routed out to the high density "bus" connectors.

As a rule of thumb - the first three 16 bit ports A, B, C on the ARM will be routed out to 2.54mm headers - based on an Arduino compatible theme. The higher ports D,E,F,G, H,I,J & K will be routed to their own double density connectors at either end of the pcb. This format will give maximum flexibility, for the larger pin packages, including memory and FPGA devices.

|

| Trial Fitting a 208 pin processor and a 72Mbit 3nS SRAM |

This arrangement will allow unique breakout for up to 156 GPIO signals (The 208 pin STM32F746 or STM32F439BGT6 have a maximum of 166 GPIO lines).

The signals unlikely to leave the board are the clock oscillators PC14, PC15, PH0, PH1, the JTAG/SWD/ST- link signals PA13, PA14, PA15, PB3, PB4 - which will have their own header.

External Memory Connector.

This 64+4 pin connector handles 32 data lines, 24 address lines and control signals.

LCD Display Connector.

This 64+4 pin connector handles 24 bits of RGB data, synchronisation signals and pixel clock along with other LCD control signals. It is arranged such that a flexible plastic connector (FPC) common on LCD screens can be easily interfaced .

Clearly a work in progress - the weekends are just to short.